Case Studies

Re-location of 24 mould tools to Replas Machinery

Replas are often asked to support companies who are having issues with their existing moulding supplier. In March 2010, we were approached by a company whose existing supplier was in financial difficulty and on the brink of collapse. Many parts had already been on order for several weeks and the customer was not aware of the situation. The customer was faced with the need to find a new home for 24 mould tools and required several parts very urgently.

After receiving a phone call in the morning, we promptly met the customer for the first time at the site that afternoon, collected the tools in our transport and brought them back to our company.

The customer provided us with sample mouldings, drawings and a list of tools and asked us to provide quotations the next day. This was not straight forward, as many of the products had been in existence for over 20 years and so the materials referred to on the drawings were no longer available, or even recognised. Many of the tools had interchangeable inserts and cores and we had little instruction about which parts belonged to which tools.

Despite all the hurdles, using our experience and our extensive network of suppliers, we were able to source the specified or equivalent materials and begin production of the first parts less than 3 days after the tools were collected.

We are still working with the customer who is very pleased with our service and regularly comments that the mouldings are of superior quality to those made by the previous moulder.

Two-part Overlay Semi-Automatic Moulding: Control Knob Overlay

Control knobs and valves fitted to therapeutic medical mattress are produced by Replas.

There are 19 control knobs and valves located down the side of the mattress which can be rotated to allow inflation of deflation of individual cells.

To provide relief where a patient has a vulnerable area, such as a wound or ulcer, to off load the pressure point the adjacent cell can be easily deflated

Several years previous Replas was asked to build soft a series of development tools whilst the product was developed and tested for a low volume product. So successful and functional the product was to be introduced on the customer’s flagship model. The product would require some alterations to improve its look, ergonomics and reduce cost to suit a higher volume product.

The client’s specification required a positive grip on the Control Knob for quick rotation and ease of use by medical staff. Volumes were to be modest so tooling costs had to be minimized whilst achieving a quality and ergonomic part to suit the application.

To stay within a modest tooling budget Replas proposed a semi-automatic process to produce a two part “overlay” moulding.

The reduce piece price cost the ‘hard’ shell moulding would be moulded on a fully automatic 2 impression tool, moulded in white Exxon Polypropylene.

To reduce customer’s final assembly time and cost the knob also had a build in clip and orientation feature for quick engagement to the Control Valve.

The Knob is then inserted into the second stage tooling and a tactile Thermoplastic Elastomer (TPE) overlay plastic (a grade of PTS Thermoflex was chosen for its excellent adhesion to polyproylene), moulded in the company’s corporate blue colour is injected over and around the hard shell. The result gives the desired “feel and grip”, and also provided an arrow indicator and thus removing the need for an additional printing process again keeping cost down.

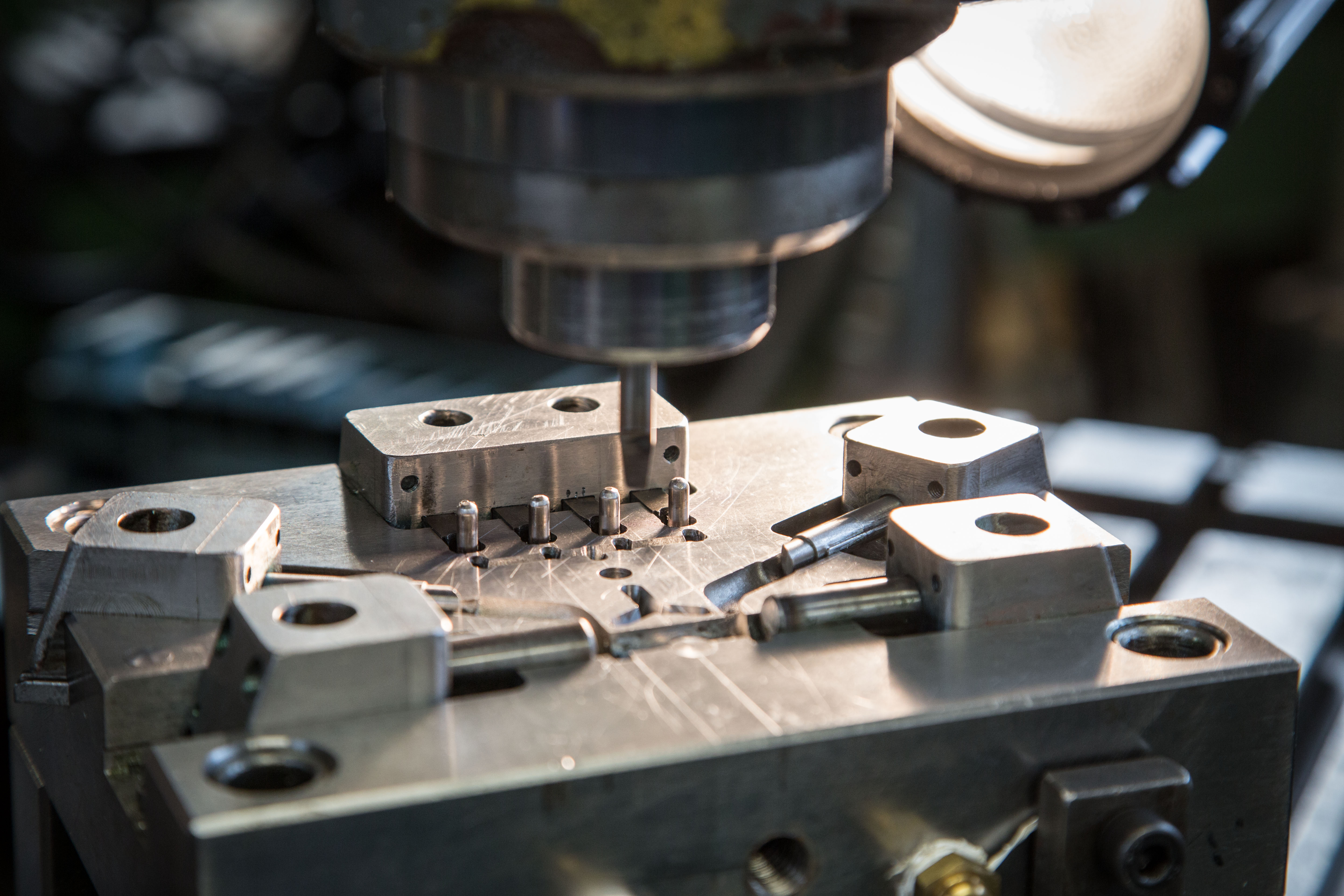

Transferring Injection Moulds between injection moulding service providers

Replas Machinery serve many companies who suffered quality or service issues with previous injection moulding suppliers.

In recent times, a UK engineering firm and manufacturer approached us after being let down badly by their UK supplier. We met with the customer and discussed their specific needs and requirements. What they needed was a supplier that they could trust, who would provide high quality output that was repeatable and a service that was reliable. The variety of items they wanted produced had to have consistent dimensions and made to very strict tolerances.

We got to work for them straight away and transferred their existing moulds from their current suppliers. Using our expertise and experience, we were able to adapt the moulds to match them to he right capacity machinery to achieve the desired quantities of output. During the process, we made the necessary quality improvements to the injection moulds to meet the standards the customer was looking for.

The customer was so impressed with the quality and accuracy of the custom items we produced, that they subsequently transferred their injection moulding from their overseas supplier to us too. To achieve the high levels of quality the customer was looking for, we made significant improvements to the moulds once transferred for a smooth, high quality production process, quality products and a satisfied customer